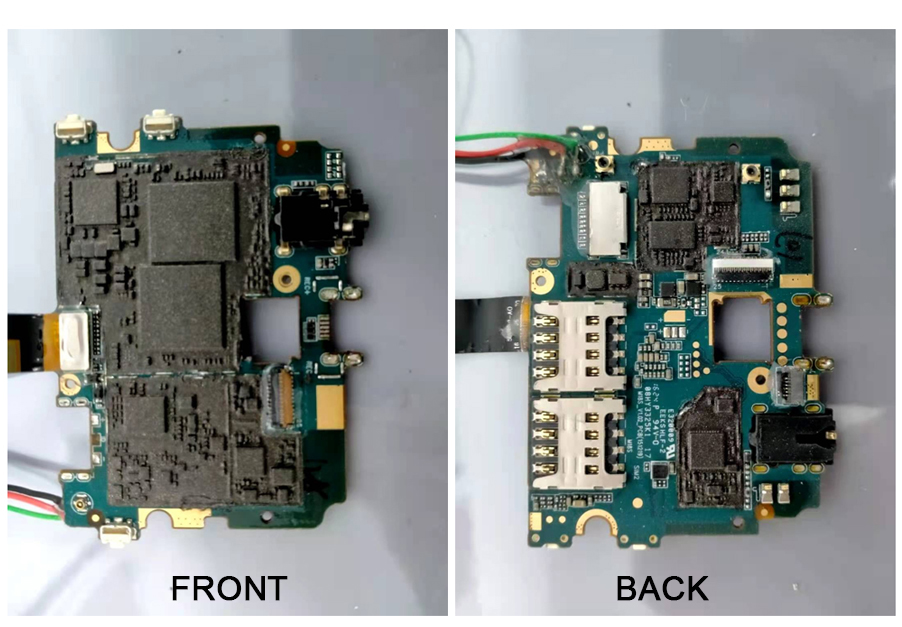

EMI-867 is a composite coating that is mainly applied to the circuit board PCBA. It is a functional coating that allows PCBA to have a strong PCBA waterproof ability after construction. It also has the ability to replace the PCBA to shield radio frequency (EMC) metal shield. The nature of the EMI-867 material is a soft coating that can be easily stripped from the PCBA surface, allowing engineers to facilitate maintenance work on the PCBA circuit board.

EMI-867 has strong covering protection for electronic components on PCBA. The film formed after spraying has strong tensile force and surface adhesion. For improving the anti-rolling and resistance of electronic components on PCBA Weak fall ability helps a lot.

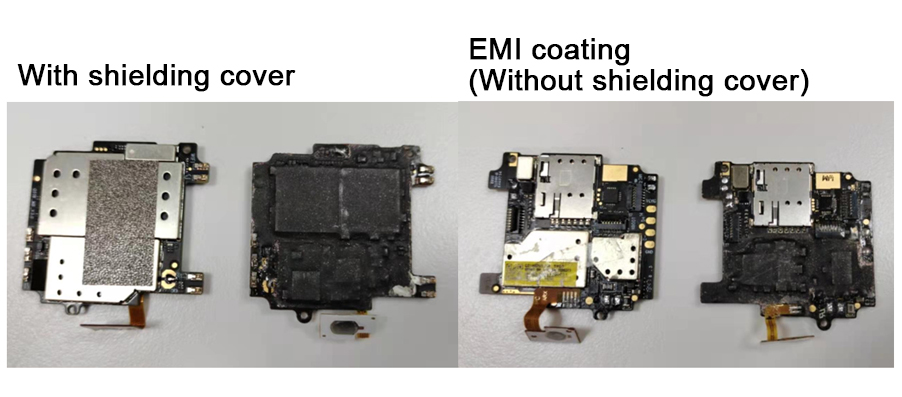

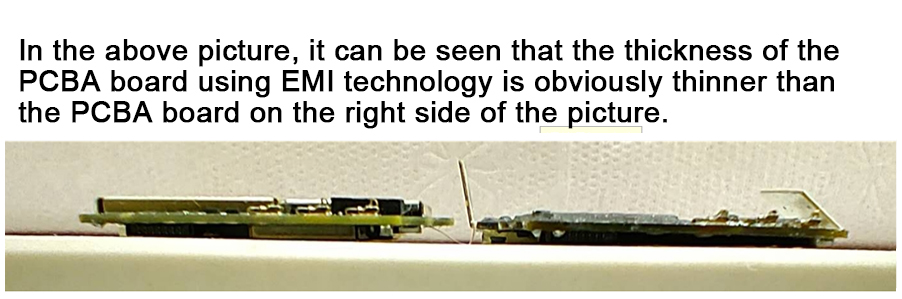

The thin film formed by EMI-867 after spraying can protect high-frequency radiation (HF) and low-frequency electric fields (LF), and can completely replace the radio frequency shielding cover on the PCBA board. Therefore EMI-867 can be greatly reduced The thickness of the customer's product shell. For example: the shell of smart phones and smart watches can be reduced in thickness.

The film formed by EMI-867 spraying is very thin and soft, suitable for spraying on flexible circuit boards. Flexible circuit boards are the future trend, but it is impossible to install a metal shield that shields radio frequency (EMC) on its surface. Through EMI-867 material can easily solve this problem.

The material of EMI-867 has both thermal conductive metal and graphene, which is comprehensive for heat dissipation on PCBA, especially for chips that are easy to generate heat. Because its heat dissipation method includes heat conduction and heat radiation absorption. And the range of heat dissipation surface becomes larger. It helps to quickly cool down the heat generated by the PCBA circuit board.

EMI-867 solution is an innovative material. It will bring new experiences to the design of various electronic products.